Air Cooled Condenser

published 08/042019The steam condensation takes place in finned tubes arranged in a single tube row. Atmospheric air is forced through the fins of these tubes thanks to axial flow fans in order to evacuate condensation heat. Tubes are grouped in elements called tube bundles. One bundle contains 38 finned tubes. Bundles are placed on a “A” shape structure above cooling fans.

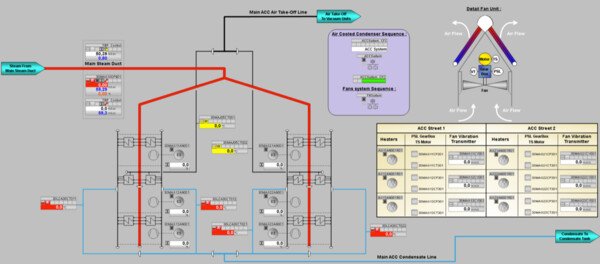

Each cooling fan is associated to 12 bundles forming a module. The air-cooled condenser is made of 2 lines of 3 modules called "streets". The ACC is thus composed of 6 modules with a total of 6 fans and 72 bundles.

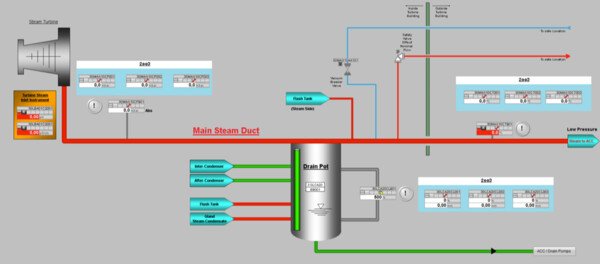

The steam coming from steam turbine flows in the main steam duct to the condenser. This duct distributes steam in 2 different branches called risers. Each riser is connected at the top of the condenser to a steam distribution manifold. Steam enters in the primary tubes connected to the manifold along each street.

Steam condensation is achieved in two steps in the primary tubes first then in the secondary tubes.

In a first condensation step, steam is partially condensed in the primary tubes and flows from tube top to bottom together with condensates. Remaining steam is collected with condensates in condensate collectors running along each side of the street and connected to the bottom of the tubes. About 90% of the total steam flow is condensed during this first condensation step.

The remaining steam flows in the condensate collectors to the secondary tubes connections. In the second condensation step the steam flows from tube bottom to top while condensates are flowing downwards back to the headers. Incondensable gases are thus concentrated at the top of the secondary tubes that are connected to the air extraction system via the air take-off line.

This counter flow condensation step has the advantage of reheating the condensates and avoids part of the sub-cooling caused by condensation with relatively high incondensable gases concentration. Incondensable gases are removed from the ACC system at top of secondary tubes thanks to the suction created by the air extraction system.

The condensates collected in the condensate collectors of each street flow by gravity to the condensate tank via the condensate piping.

The condensate tank is connected to the main steam duct by the balancing line in order to recover a part of the pressure drops and a part of condensate sub-cooling from the air cooled condenser. In case of condensate boiling due to pressure fluctuations, the balancing line will drive the produced steam to the main steam duct and avoid steam backflow in the condensate piping.

Drains from the condensation occurring in the main steam duct are collected in a drain pot located at the lowest duct level. This drain pot also receives drains from air extraction system condensers and the flash box (supplied by others). All these drains are evacuated to the condensate tank by drain pumps (2 x 100%).